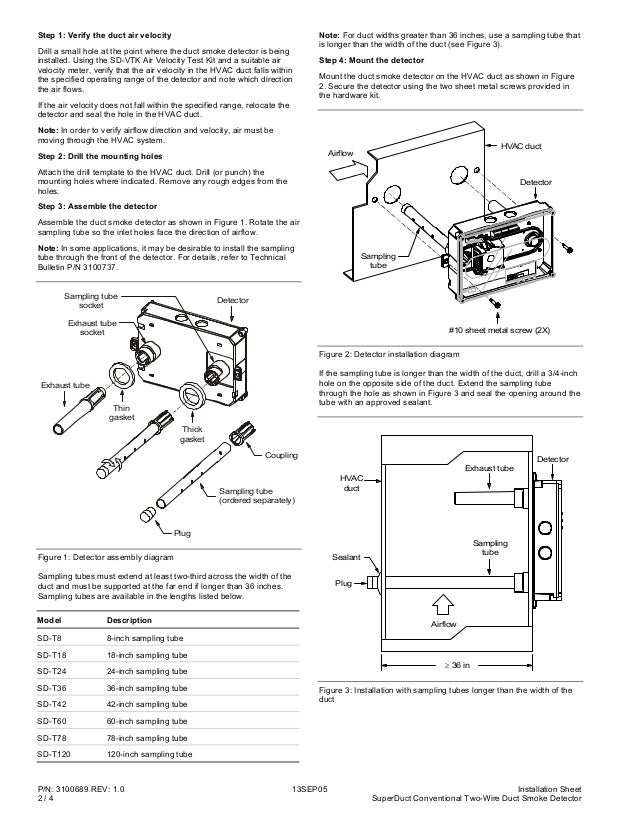

St 10 for duct widths of 6 to 1 0 st 25 for duct widths of 1 0 to 3 0 st 50 for duct widths of 3 0 to 5 0 requires support.

Duct smoke detector sampling tube installation.

Installation instructions for the duct smoke detector a.

Duct detectors smoke detection installation.

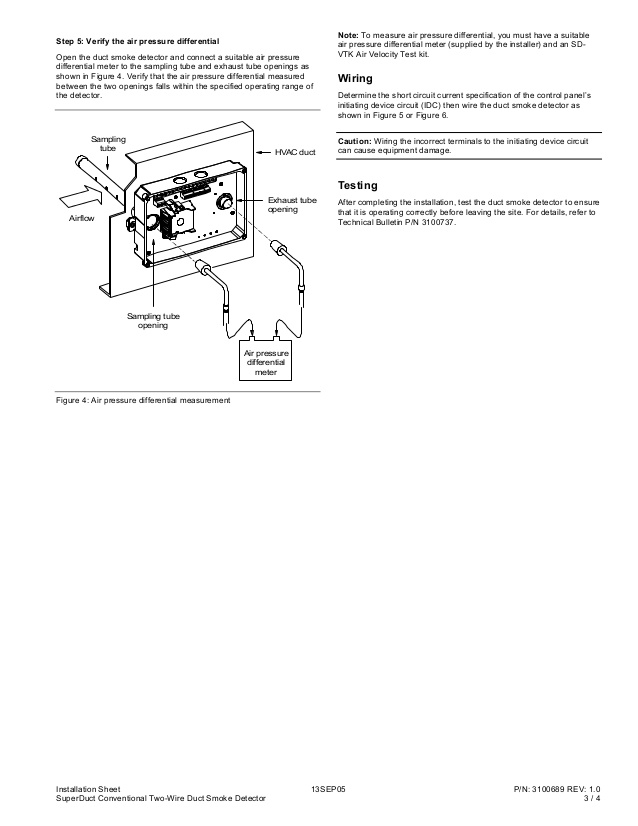

The specified operating range of the detector make sure the sampling tube air holes are not obstructed and are facing the hvac system airflow.

The sampling tube end cap included with the detector is critical to proper operation of the duct smoke detector.

4 6 p n 3101210 rev 02 iss 28jan13.

The sampling tube end cap included with the detector is critical to proper operation of the duct smoke detector.

High performance hvac on march 11 2020 at 10 27 pm.

The end cap is needed to create the proper air flow to the sensor of the duct smoke detector.

See table 1 on page 3 to determine the inlet tube required for different duct widths.

4 detector installation 4 1 verify duct air flow direction and velocity.

Do you know if it is a code requirement to support sampling tubes greater than 3 at the opposite end of the duct detector.

The inlet sampling tube is to be located between blades to avoid blockage of the airflow past the tube.

Standard location when factory mounted will be on the side opposite the damper actuator.

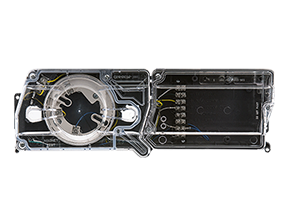

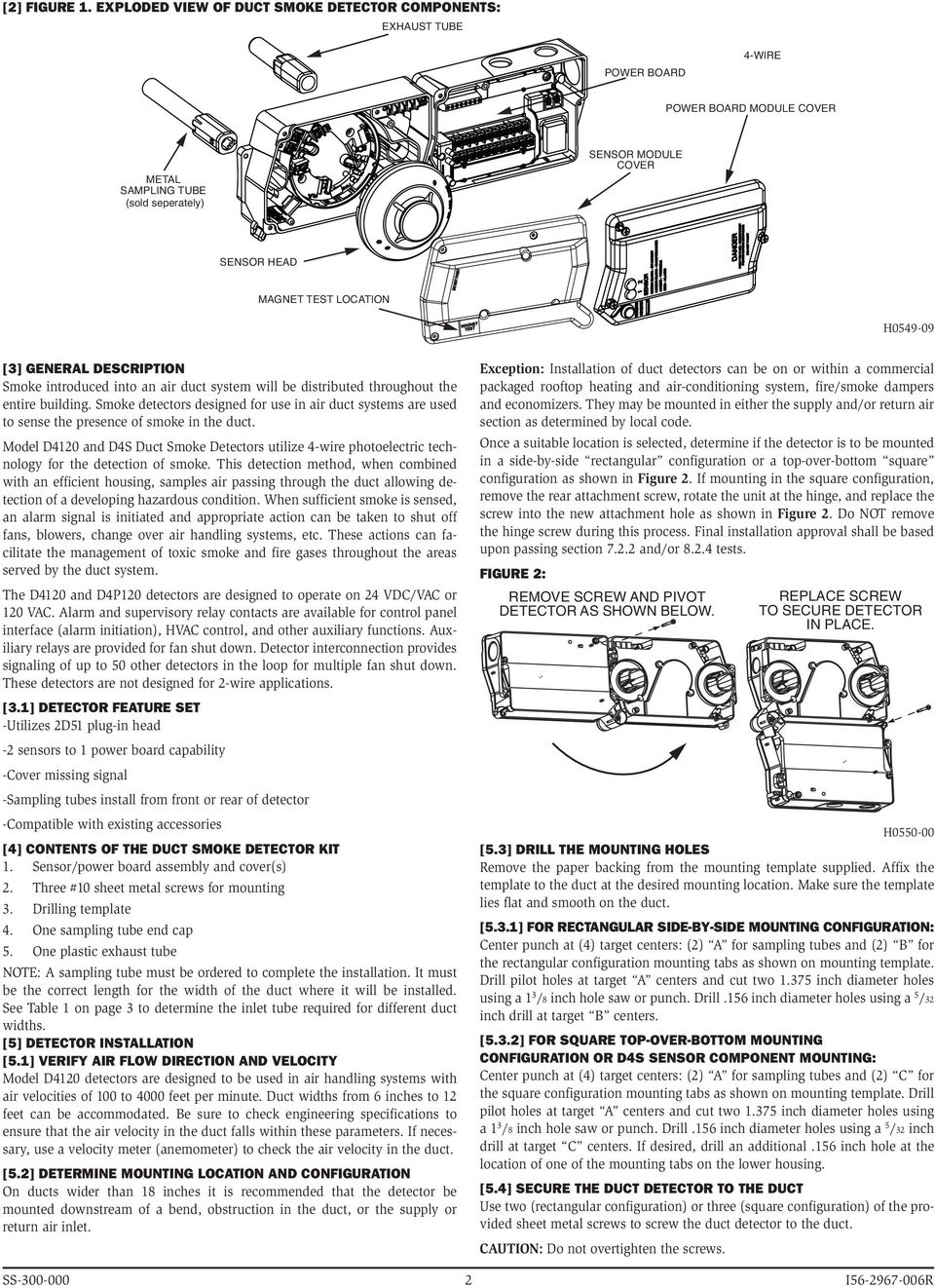

Sensor power board assembly and cover s 2.

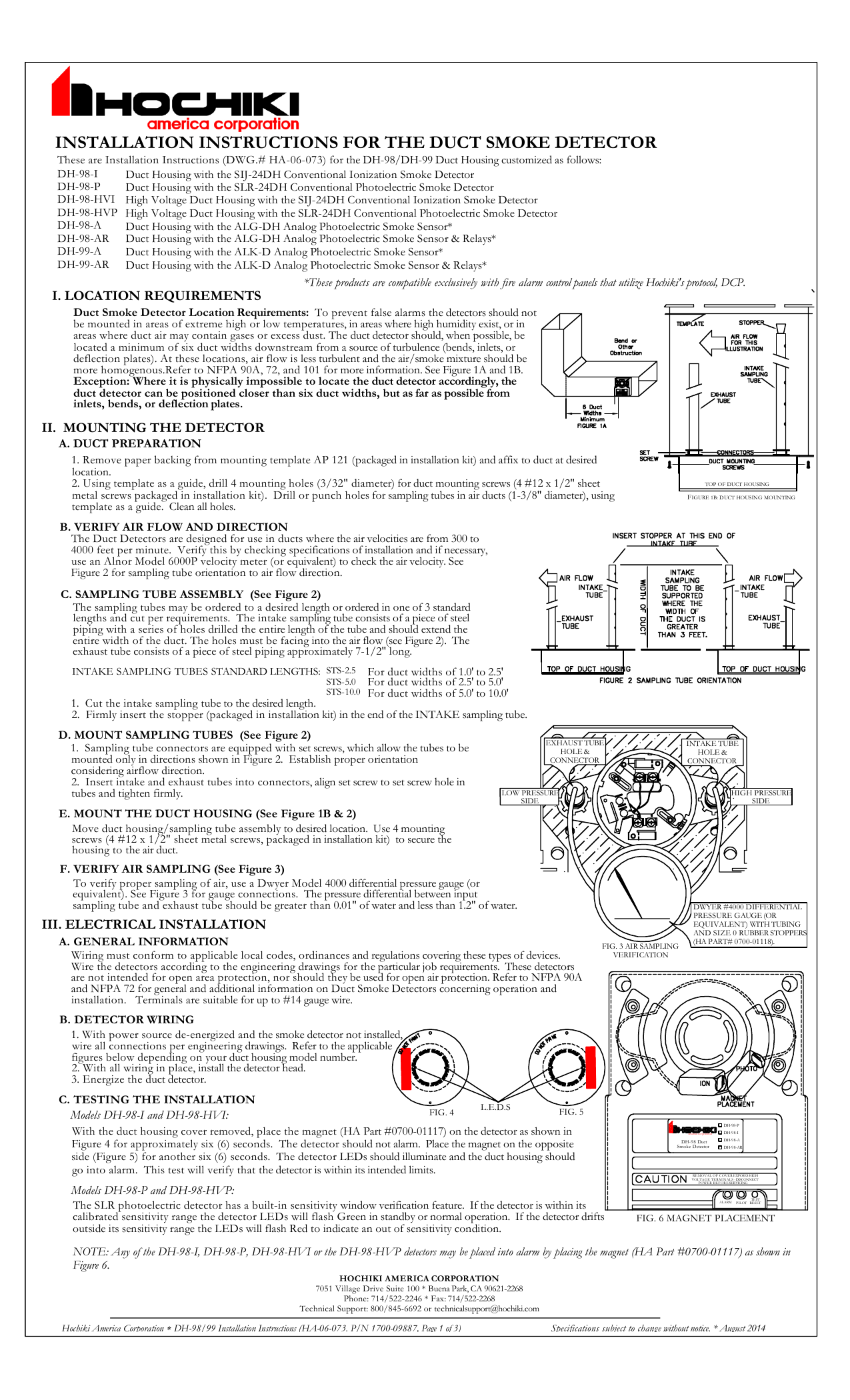

Sampling tube assembly see figure 2 the duct detectors are designed for use in ducts where the air velocities are from 300 to 4000 feet per minute.

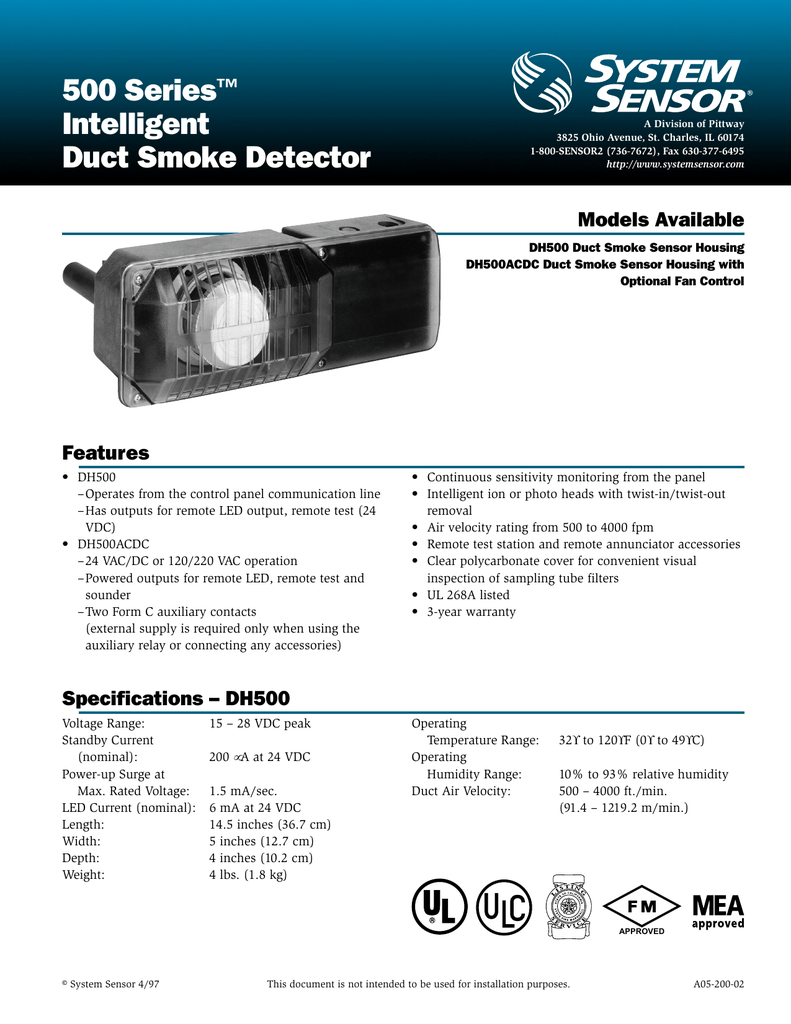

Sampling tubes install from front or rear of detector compatible with existing accessories 4 contents of the duct smoke detector kit 1.

The end cap is needed to cre ate the proper air flow to the sensor of the duct smoke detector.

Verify this by checking specifications of installation and if necessary use an alnor model 6000p velocity meter or equivalent to check the air.

Furthermore intentions for using duct smoke detectors should not be a substitute for area smoke detectors.

Sampling tube installation the ad2 series duct smoke detectors use a specially notched sampling tube which may be ordered separately in one of four standard lengths.

Duct preparation the duct detectors are designed for use in ducts where the air velocities are from 300 to 4000 feet per minute.

Three 10 sheet metal screws for mounting 3.

Once any sampling tube length adjustments are made plug the end of the sampling tube with the provided end cap.

Prior to the installation of the damper and smoke detector.

One plastic exhaust tube.

Verify this by checking specifications of installation and if necessary use an alnor model 6000p velocity meter or equivalent to check the air velocity.

For proper air sampling duct pressure should be a minimum of 0 01 inches of water.

Once any sampling tube length adjustments are made plug the end of the sampling tube with the provided end cap.

E pdd duct smoke detector installation sheet operation the duct smoke detector s primary purpose is to provide early.

A sampling tube must be ordered to complete the installation.